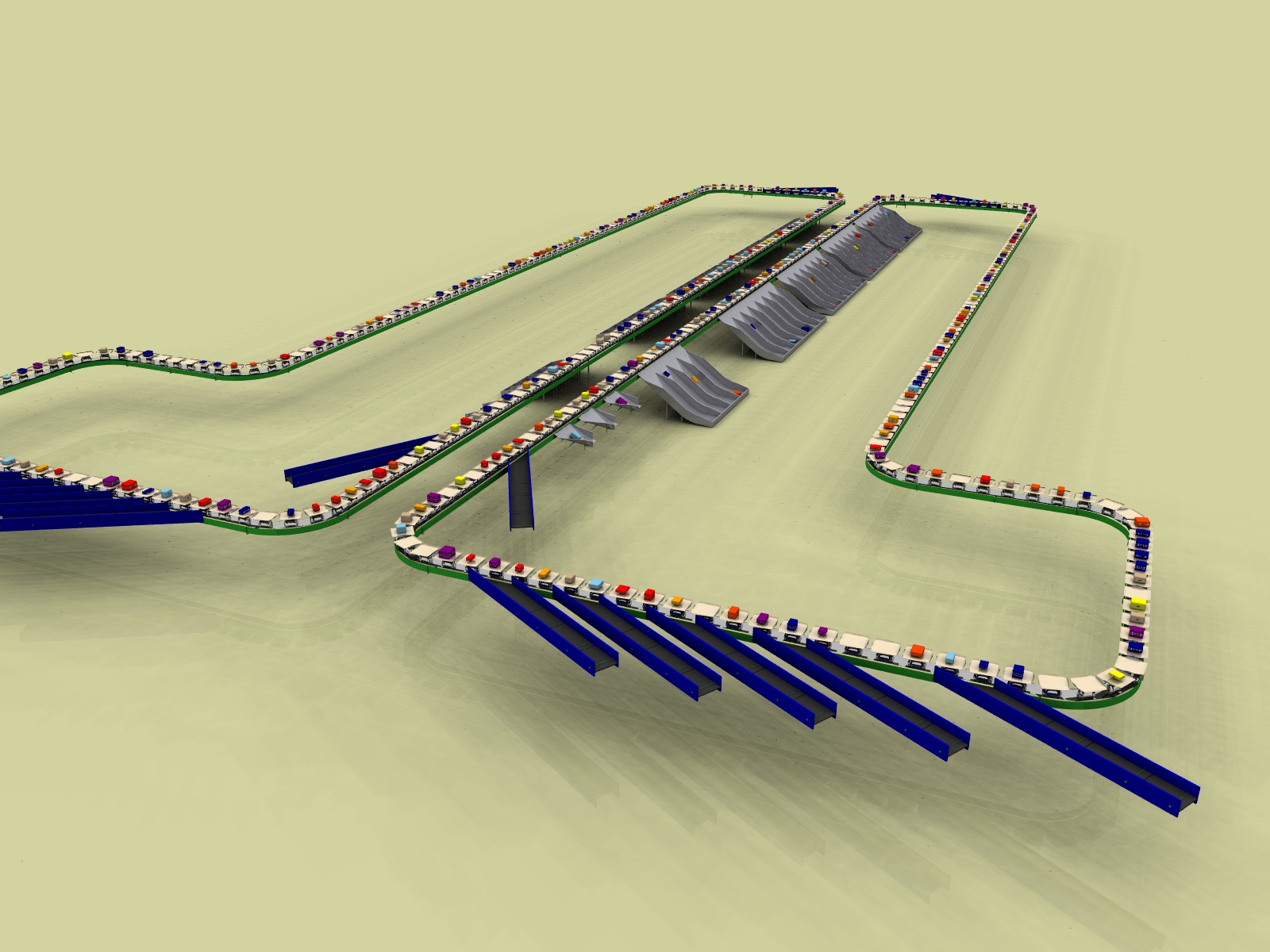

Addis Ababa resolves ‘bag clogging’ issues with additional Early Bag Store and Transfer systems Ethiopia’s Addis Ababa Bole International Airport is to solve its main baggage throughput issues during peak periods with an upgraded Departures BHS that features additional systems and storage to cater for Early Bag Store (EBS) and Transfer baggage.

Ethiopia’s Addis Ababa Bole International Airport is to solve its main baggage throughput issues during peak periods with an upgraded Departures BHS that features additional systems and storage to cater for Early Bag Store (EBS) and Transfer baggage.

The airport operators, Ethiopia Airlines Enterprises (EAE), has awarded the £2.5 million BHS project to EBS and Transfer baggage specialist, Daifuku Logan, part of the global Daifuku ABH Division, and is anticipating the upgraded and expanded Departures system to be fully operational by April 2014.

Daifuku Logan supplied a baggage system over 12 years ago when the airport processed around one million flight passengers a year. Since then the number of passengers using Addis Abba Bole has risen to six million and is growing. The airport estimates 50% of these are transit passengers in need of baggage transfer to a connecting flight, and more and more airline travelers are bringing bags early to the airport, creating on-going ‘clogging’ issues in processing bags during busy and peak times.

Addis Ababa is not untypical of the impact that EBS and Transfer baggage is having on normal baggage operational throughput at many other international airports around the globe.

As a result, EAE brought in three leading baggage handling system integrators to put forward design solutions to enable the airport to provide faster throughput. Daifuku Logan’s project and design team for Addis Ababa used a key element, its proven and advanced computer simulation programme, to determine the most effective and reliable solution.

Daifuku Logan’s winning proposal called for the addition of a system that would handle the early bags and transfer bags, and to provide a facility for the storage of early bags, thereby freeing up the system and preventing clogging during normal periods.

Ron Osborne, Managing Director of Daifuku Logan, said of the winning design: “Rather than propose faster sortation, or tighter window timeframes for accepting baggage at Check-in, we went for the option of additional facilities to cater for EBS and transfer baggage, which is more than 50% of the airport’s entire baggage throughput. The airport accepted the benefits that this scheme would bring and they outweighed the higher costs and reliability and expense issues of faster baggage handling.”

In addition to the expansion of the Departures system, EAE is placing an additional £1 million contract with Daifuku Logan to refurbish the existing baggage handling equipment. This is an essential exercise that will ensure that the upgraded system will have the improved level of reliability required to meet the requirements of the system upgrade.

Daifuku Logan has already carried out a comprehensive mechanical and electrical survey that will provide the basis for the refurbishment programme.

Rapidly growing Tianjin Binhai International chooses Logan sorter for new terminal BHS project

Logan sorter for new terminal BHS project

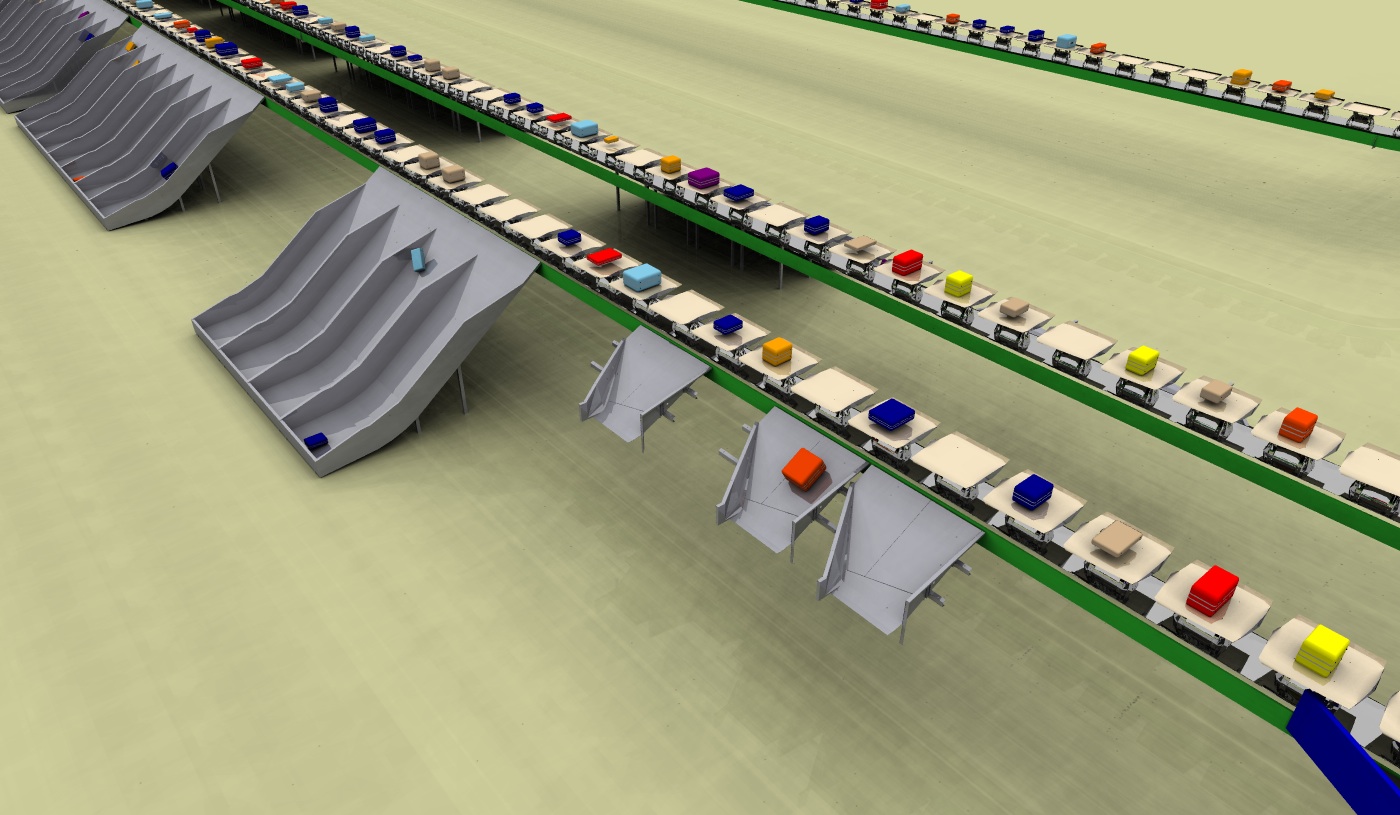

Following a highly competitive pitch to provide fast and reliable sortation equipment for Tianjin Binhai International Airport’s new terminal project, Logan Teleflex’s latest advanced technology 700RF Tilt Tray Sorter has been selected as ‘best in market’.

China’s experienced and successful airport design consultants, Civil Aviation Logistics Technology Company Ltd (CALTCO), part of CASRI, awarded the Logan KSEC Joint Venture company with a £2.6 million contract to supply and install two Tilt Tray Sorters. The project will be implemented in a phased approach beginning this month, with the next generation Tilt Tray Sorters being installed from Christmas onwards.

Logan KSEC will provide control panels, HMI, PLCs, software, wiring materials and will undertake site testing, commissioning and training. As part of the project, CALTCO is also working with local supplier and subcontractor, Chandga Conveyor Company, to provide all steelwork and conveyors.

The airport is currently on a growth curve and needs to keep pace in being able to handle baggage for an increasing number of airline passengers. In 2010, the airport handled over 7 million people a year – a 26% increase in passenger traffic over 2009 passenger figures. Tianjin follows in the footsteps of other key airports in China, such as Kunming and Wuhan, to employ Logan’s new 700RF TTS for fast and accurate baggage sortation and a capability of 5,400 tips per hour, or at speeds of 1.8 metres per second.

Tianjin follows in the footsteps of other key airports in China, such as Kunming and Wuhan, to employ Logan’s new 700RF TTS for fast and accurate baggage sortation and a capability of 5,400 tips per hour, or at speeds of 1.8 metres per second.

Dave Reynolds, International Sales Director for Logan Teleflex, commented: “CALTCO have been successful in winning a number of airport projects in the People’s Republic of China recently and we are delighted that they believe our Tilt Tray Sorter to be ‘the best in market.”

The newest Model 700RF Tilt Tray Sorter represents the most advanced sorter available today. Particular benefits for today’s modern airport requirements include an electrical tip action, controlled via a radio frequency signalling system, which permits unprecedented levels of control over the items to be handled.

To compliment the ‘Best in Class’ Sort Machine, Logan Teleflex has developed and patented a ‘Best in Class’ Induction system. Inductions are available at either 30 or 45 degree angles to suit the application, and include ‘Stop/Go’ induction for low throughput applications; these feature product stability and positioning check during the induction process, and re-synchronisation of these items in a much more controlled manner. Aside from being an international airport and a hub airport for Tianjin Airlines and a focus city for Air China, Tianjin has become one of the major air cargo centres in the People’s Republic of China and has an airport footprint on par with Amsterdam Schiphol. Tianjin is a metropolis in northern China and one of the five national central cities of the People's Republic of China.

Aside from being an international airport and a hub airport for Tianjin Airlines and a focus city for Air China, Tianjin has become one of the major air cargo centres in the People’s Republic of China and has an airport footprint on par with Amsterdam Schiphol. Tianjin is a metropolis in northern China and one of the five national central cities of the People's Republic of China.