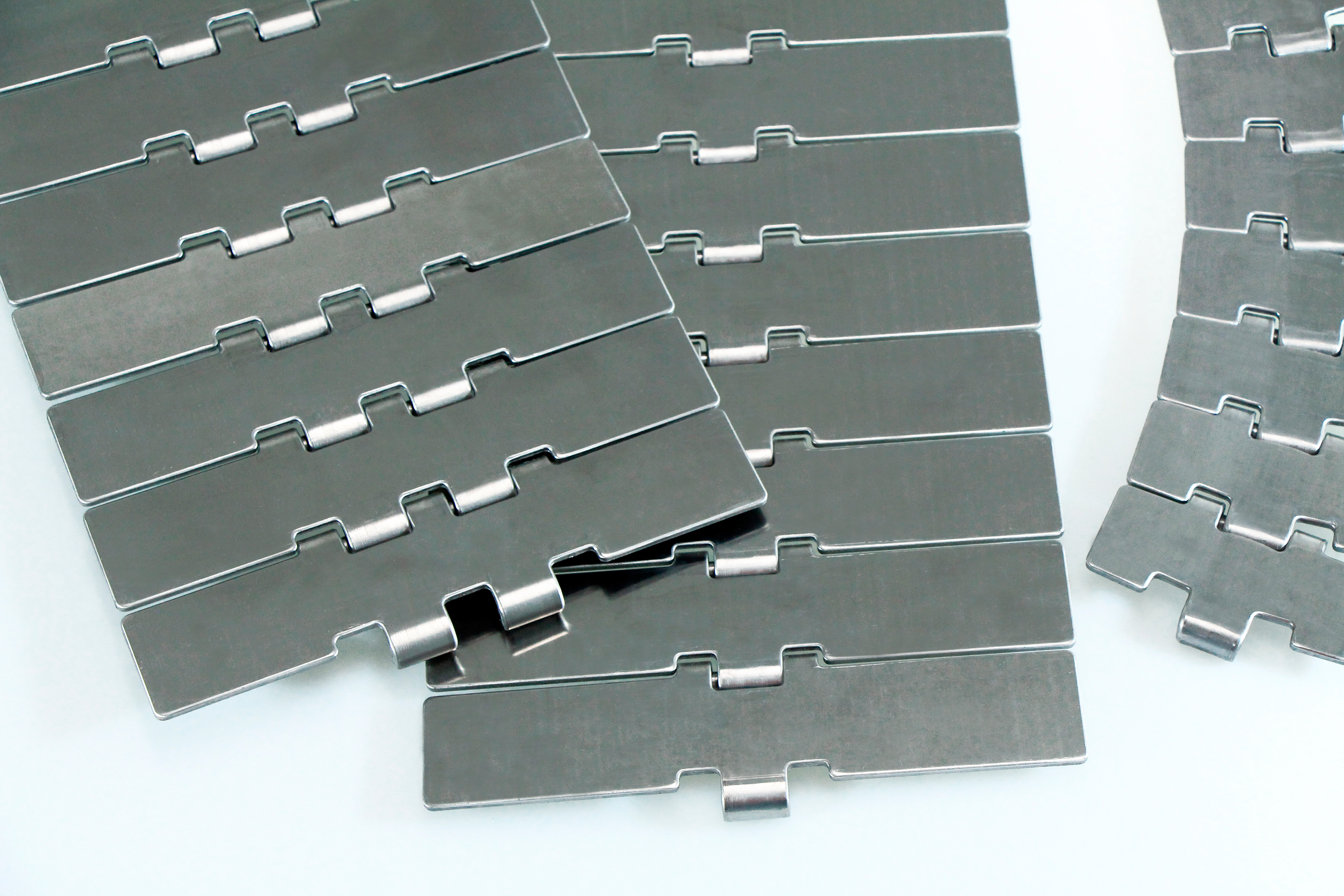

RAISING THE BAR: New Range of Premium Steel Chains from Ammeraal Beltech Modular for smooth, safe, swift production lines Ammeraal Beltech’s uni-chains® range of modular conveyor belts and chains now offers an increased choice of materials with the introduction of high-performance uni-chains PLUS+ hardened stainless steel chains. Of particular interest for glass container production as well as food and beverage packaging, the new chains – with external dimensions meeting international slat chain standards -- feature an innovative surface for extra stability of products.

Ammeraal Beltech’s uni-chains® range of modular conveyor belts and chains now offers an increased choice of materials with the introduction of high-performance uni-chains PLUS+ hardened stainless steel chains. Of particular interest for glass container production as well as food and beverage packaging, the new chains – with external dimensions meeting international slat chain standards -- feature an innovative surface for extra stability of products.

Setting new standards

Ammeraal Beltech already offers a globally-established portfolio of steel and plastic slat chains which have set industry standards in many arenas. The company’s commitment to continuous improvement has led them to bring to market the uni-chains PLUS+ range to increase line efficiency and production speeds; lower maintenance requirements and extend wear life; and, as a result, deliver significant reductions in cost of ownership.

Product profile The uni-chains PLUS+ special work-hardened chrome-nickel stainless steel chains feature a flatter surface, with lower surface roughness, reduced gaps between plate links to help eliminate product ‘tripping’, and profiled link edges for improved side transfers and less accumulation noise. Together with the special surface finish, the strong metal chains provide, overall, more stable product handling, and – of special value on bottling lines and made-to-order food lines – very low slide resistance. uni-chains PLUS+ steel slat chains are available now through Ammeraal Beltech’s worldwide sales and service network.

The uni-chains PLUS+ special work-hardened chrome-nickel stainless steel chains feature a flatter surface, with lower surface roughness, reduced gaps between plate links to help eliminate product ‘tripping’, and profiled link edges for improved side transfers and less accumulation noise. Together with the special surface finish, the strong metal chains provide, overall, more stable product handling, and – of special value on bottling lines and made-to-order food lines – very low slide resistance. uni-chains PLUS+ steel slat chains are available now through Ammeraal Beltech’s worldwide sales and service network.

Product information: www.ammeraalbeltech.com/plus

Sales and Service network: www.ammeraalbeltech.com

A WORLD FIRST – BOTH EC AND FDA FOOD CONTACT APPROVAL FOR AMDOUGH ROTARY MOULDER BELTS

AMDOUGH ROTARY MOULDER BELTS

Ammeraal Beltech’s AmDough endless woven belts are the first to offer the biscuit bakery industry full food contact approval. They are declared compliant with EC regulations, in addition to their already existing FDA approval.

AmDough endless woven belts, since their invention in 1951 by Ammeraal Beltech’s founder, have always been a mainstay of the bakery market’s rotary biscuit moulding process, and can today extract any type of biscuit across a range of different belt layouts and widths. The company monitors the needs of this specialist market on a regular basis to ensure their AmDough range continues to meet changing industry requirements – not only higher belt speeds and wider belts, but also the ability to handle gluten- or fat-free biscuits, or biscuits with fruit content – without in any way compromising extraction efficiency.

‘Hygiene and high performance’

‘AmDough endless woven splice-free construction and specially-designed selvedges guarantee continuous cookie extraction combined with food safety’. says Giuseppe Allais, Ammeraal Beltech’s Industry Segment head for the Food Business, ‘and their combination of hygiene and super performance have made them the first choice for the great majority of biscuit manufacturers, worldwide. They are the recognised industry standard.’

Full details of the AmDough portfolio from Ammeraal Beltech, as well as information on the company’s full range of belting products for the food industry, are available at www.ammeraalbeltech.com, or directly from food industry expert Giuseppe Allais at gallais@ammeraalbeltech.it.

MAJOR NEW AMMERAAL BELTECH FACILITY OPENS IN CHINA:

A key investment in global manufacturing capabilities Global process and conveyor belting specialists Ammeraal Beltech have officially opened a major new wholly-owned manufacturing facility in China. This plant will increase the company’s production capabilities and help better serve markets in China, the Asia Pacific and the Americas. Ammeraal Beltech’s products and solutions feature in many key industries including food processing, automotive, textiles, paper and print, airports, logistics, wood, and tobacco.

Global process and conveyor belting specialists Ammeraal Beltech have officially opened a major new wholly-owned manufacturing facility in China. This plant will increase the company’s production capabilities and help better serve markets in China, the Asia Pacific and the Americas. Ammeraal Beltech’s products and solutions feature in many key industries including food processing, automotive, textiles, paper and print, airports, logistics, wood, and tobacco.

Strategic location

Strategically located in the new Fenhu Economic and Technical Development Zone, at the centre of China’s most highly-industrialised region, Ammeraal Beltech’s newly-built state-of-the-art factory and offices occupy 20,000m² of land, and are equipped with the latest eco-friendly technologies, including energy recovery systems to recover heat from cooling water. Alongside the company’s manufacturing facility in The Netherlands, the Fenhu plant is designated a major growth platform for synthetics manufacture, with provision made to enable future enhancements to the plant’s capabilities, including product portfolio extension.

Like the factory in Holland, the new Fenhu factory can supply the complete portfolio of standard belting products and accessories to Ammeraal Beltech’s operating companies worldwide. Speedy customer service is enabled by Fenhu’s excellent transport connections to Shanghai, Suzhou, and Hangzhou.

Officially opened on May 28th 2014, the Fenhu factory represents a continuing commitment on the part of Ammeraal Beltech to innovation and meeting customers’ needs in a global environment – a commitment it will confirm by participating in two major regional exhibitions in October 2014: Inter Airport China in Beijing, and CeMAT Asia in Shanghai. www.ammeraalbeltech.com